IncineratorㆍDryerㆍPower Plant Business

CNT85

The incineration and power generation business is the main business area of our company,

which is a project that contributes to environmental preservation by producing heat (steam) or electricity by incineration of various types

of combustible wastes such as industrial waste, medical waste, municipal waste, and bio mass.

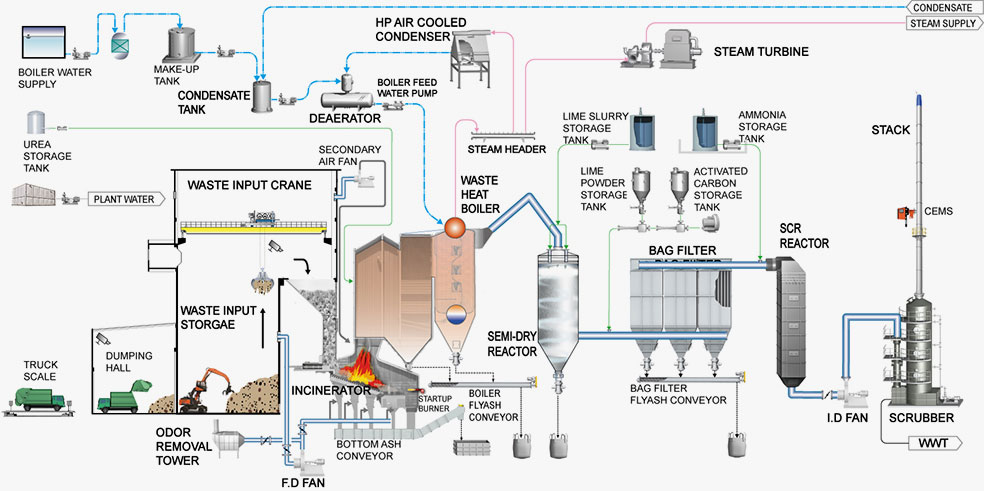

Stoker Type Incineration Power Plant

The Stoker (Moving Grate) type combustion facility is suitable for incineration a relatively large fuel size. It is a type in which fuel is charged at the top of the input hopper to inject certain amount of fuel into the combustion chamber and then slowly burn for a long residence time.

After combustion, the remnants are carried out to the outside by a bottom ash conveyor, and the combustion gas is cooled down after heat recovery through a waste heat boiler and discharged to the atmosphere after treatment of flue gas cleaning facilities at the next process.

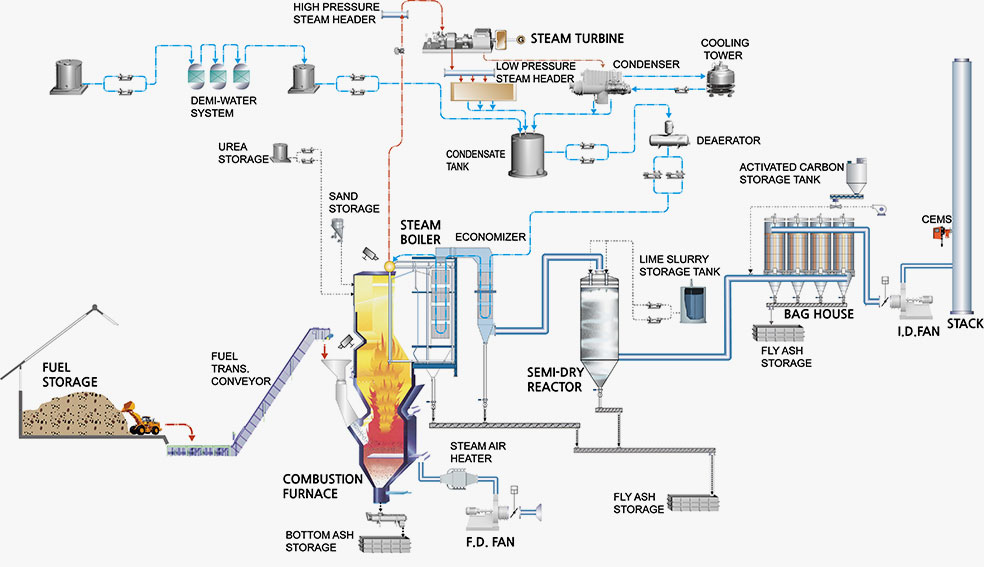

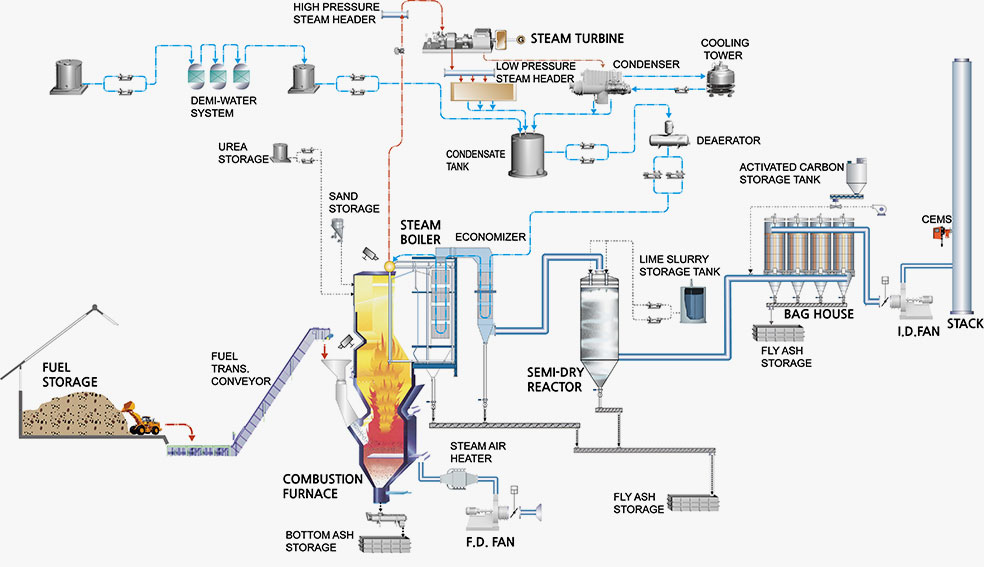

Fluidized bed Incineration Power Plant

The bubbling fluidized bed combustion (BFBC) facility evaporates moisture and rapidly burns fuel by heat accumulated in the sand in the fluidized bed, so it can incinerate a large amount of fuel with a small burning area and has a wide range of applications from low to high calorific value. Most of the ash, except for foreign substances, is transported with the combustion gas to the rear end and is collected after dust collection in the air pollution prevention facility at the rear end. The generated combustion gas heat is cooled down on the boiler located next process, and the generated steam is used for heat supply and power generation.

BFBC Incineration Power Plant

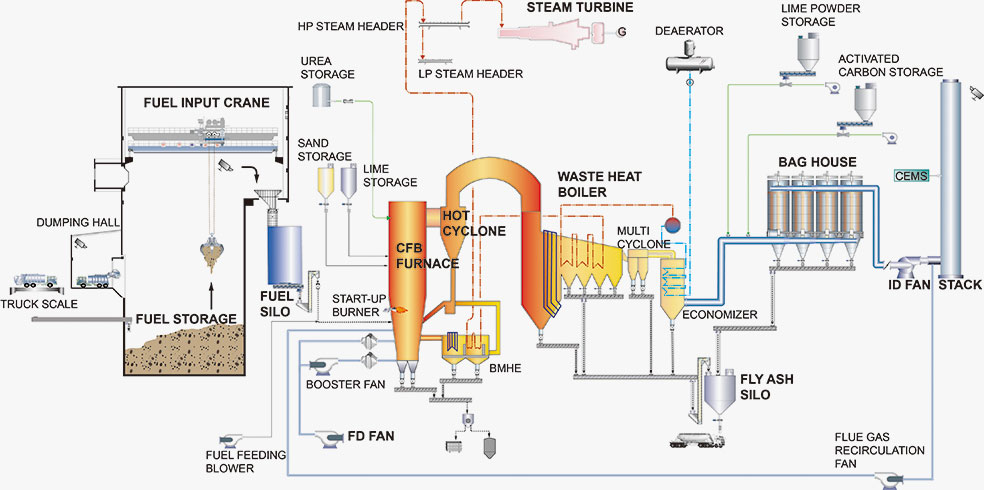

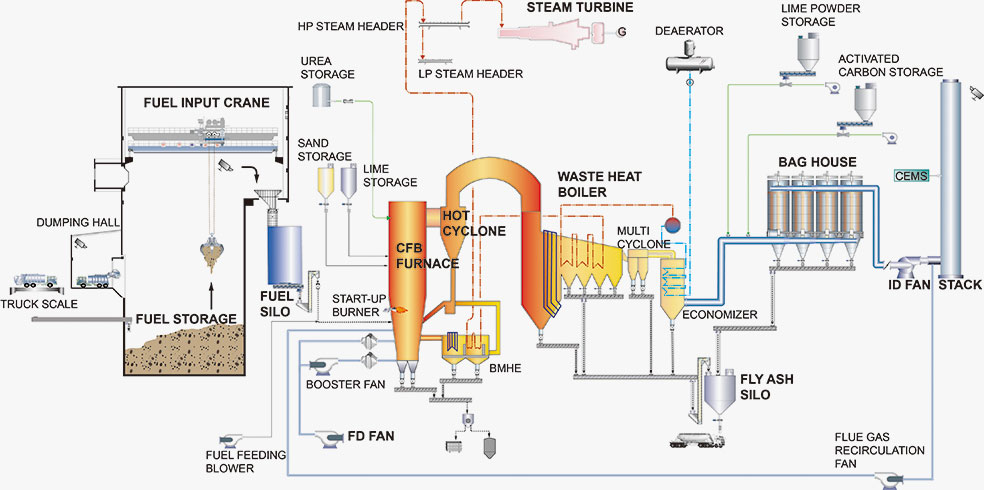

CFBC Incineration Power Plant

The external Circulation Fluidized Bed Combustion (CFBC) facilities have proven to be an effective way for large sized incineration system. In the fluidized bed, combustion gas and ash included unburning material are separated combustion gas and ash through hot-cyclone on the next process. The combustion gas is exhausted to the boiler and ash is cooled in heat exchange on lower part of the hot-cyclone, and then the ash is flowed into combustion chamber again. The combustion temperature of furnace is controlled by ash circulating ratio of hot-cyclone. The generated heat as combustion gas is cooled down by the next boiler. After heat recovery process on the boiler, the steam is used for heat supply system or power generation process.

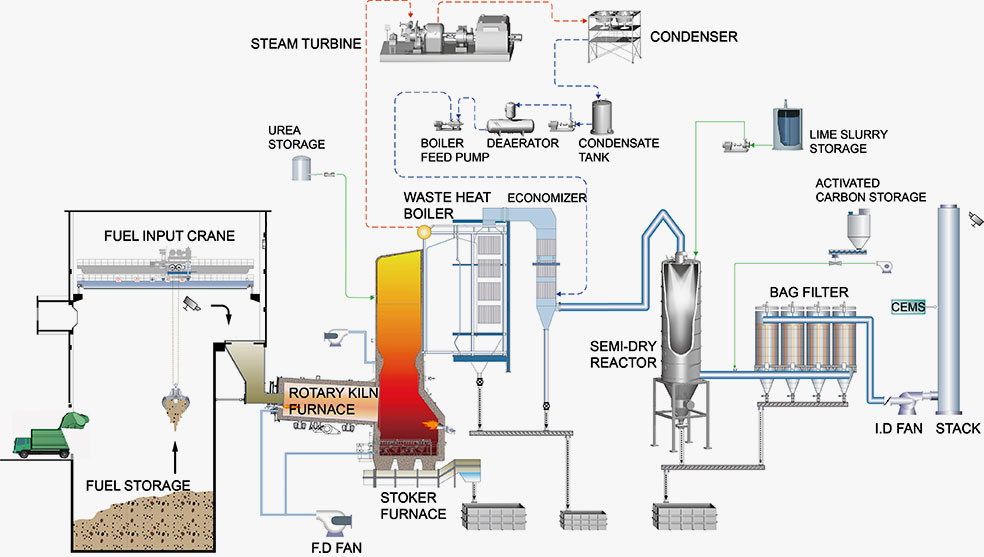

Rotary Kiln + Stoker Incineration Power Plant

The rotary kiln incineration plant is suitable for mixed incineration of a wide variety of raw materials. The rotary kiln rotates slowly, the input wastes are mixed, drying and combustion proceed sequentially, and the generated gas is completely reburned by on the next post combustion chamber. The rotary kiln can be operated alone, but it can also be applied to combustion of raw materials with high calorific value in combination with a stocker type incinerator depending on the characteristics of the fuel.

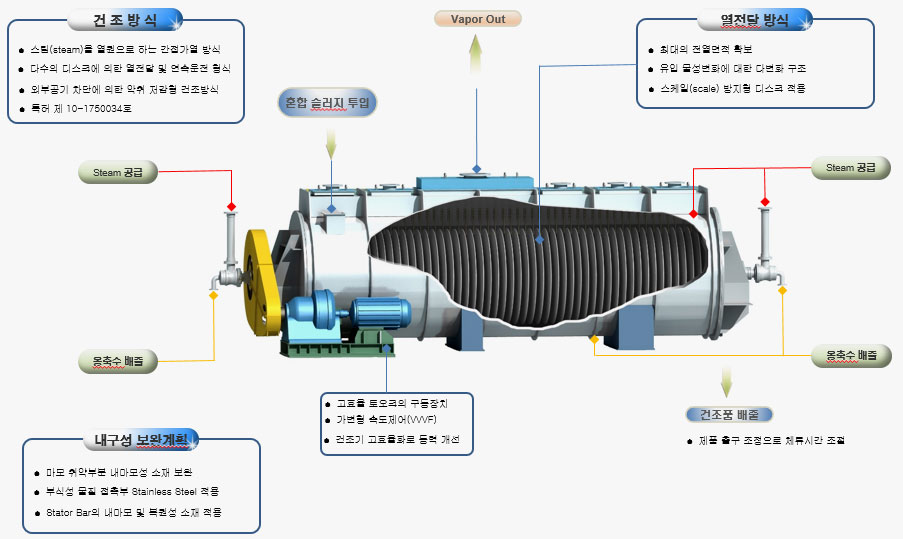

Disk Dryer

The dryer is designed for drying of sludge from municipal and industrial waste water treatment plants. The sludge is fed to one end of the dryer. The moisture is evaporated when the material is conveyed through the dryer towards the discharged end by heat of the disks and shell jacket. The rotor consists of a central pipe on which a large number of vertically arranged disks with double walls have been welded. This design results in a concentrated heating surface offering maximum evaporation capacity in a compact design.

Longitudinal View of Dryer

Front of Dryer

Complete View of Disk

Details of Disk